When planning retail displays for athletic brands, the choice between fiberglass and plastic mannequins is more than a simple material selection—it's a strategic decision that impacts aesthetics, functionality, and return on investment. As the demand for dynamic sports mannequins grows, understanding how each material performs under the specific requirements of athletic display is essential. This guide provides a detailed comparison, focusing on how fiberglass and plastic meet the challenges of showcasing sportswear with power and precision.

Material Showdown: Performance in Athletic Context

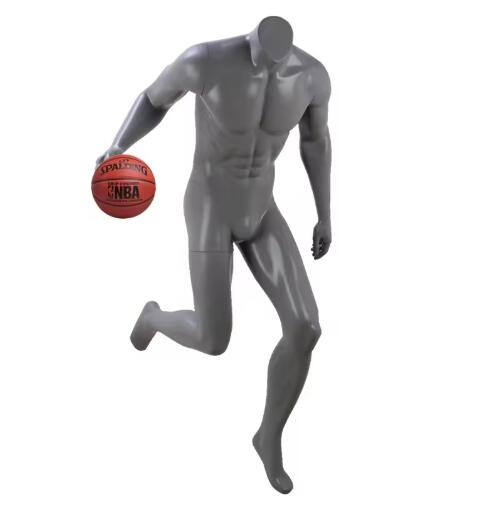

Fiberglass mannequins are renowned for their premium finish and anatomical fidelity. For an athletic mannequin intended to display high-end performance wear, fiberglass offers unparalleled realism. Its surface accepts fine finishes that can replicate skin texture and muscle definition with remarkable accuracy, making it ideal for capturing the nuanced physique of a dedicated athlete. This makes fiberglass particularly suitable for a running mannequin where the definition of calf muscles, the tension in the quadriceps, and the lean of the torso need to be visibly convincing to tell a story of speed and endurance.

However, this realism comes with considerations. Fiberglass is more susceptible to chipping or cracking if impacted. While a fitness mannequin in a robust, balanced pose may be relatively safe, those in more dynamic, off-center poses (like a climber or a dancer) could be at risk in high-traffic environments unless handled carefully. Its repair is specialized and can be costly.

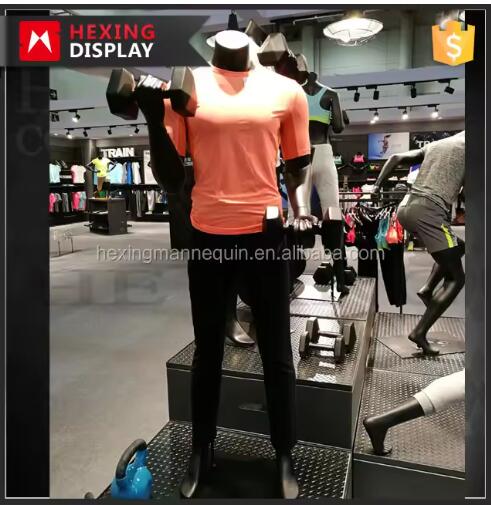

In contrast, plastic mannequins, typically made from durable polymers like ABS, offer exceptional resilience. This makes them a practical champion for high-traffic retail spaces. An athletic female mannequin in a busy chain store, frequently changed in and out of new collections, benefits from plastic's ability to withstand knocks and frequent handling without showing immediate wear. Their lightweight nature simplifies the logistics of rearranging displays, allowing visual teams to quickly adapt to new campaigns. For brands requiring numerous units of sports mannequins across multiple locations, plastic's lower initial cost and ruggedness present a compelling, budget-friendly argument.

Maintenance and Longevity for Active Displays

Maintenance routines diverge significantly based on material. Fiberglass requires a more meticulous approach. Regular dusting with a soft cloth and prompt cleaning of any stains with mild soapy water is necessary to preserve its glossy finish. Direct sunlight should be avoided to prevent fading. For a premium athletic mannequin made of fiberglass, this care preserves its high-end look, ensuring it continues to justify its higher initial investment over a long lifespan.

Plastic mannequins are decidedly low-maintenance. They can be cleaned quickly with common disinfectants and are less prone to cosmetic damage from routine cleaning. Their color is often molded throughout the material, so minor scratches are less noticeable than on the painted surface of a fiberglass running mannequin. This ease of care translates to lower long-term operational costs and less downtime for displays.

Cost-Effectiveness: A Strategic Calculation

The cost analysis extends beyond the price tag. Fiberglass mannequins command a higher initial cost. This investment buys superior aesthetics, a heavier and more stable presence (crucial for holding ambitious poses for fitness mannequins), and a longer potential lifespan if maintained properly. They are often the choice for flagship stores, high-fashion athletic brands, and permanent installations where image is paramount.

Plastic mannequins offer a lower entry point and superior durability against physical damage. Their cost-effectiveness shines in scenarios requiring large quantities, frequent pose or location changes, or in environments where mannequins might be subject to unintentional customer contact. The total cost of ownership may be lower, especially when factoring in minimal maintenance and near-zero repair needs.

Future Trends: Materials Evolving with Sport

Both materials are adapting to future trends. The push for sustainability is leading to innovations in recycled fibers for fiberglass and bio-based or recycled polymers for plastic sports mannequins. The integration of smart technology—like embedded LEDs to highlight muscle groups on an athletic female mannequin or sensors for interactive experiences—is being designed to work with both material types, though modular designs in plastic may offer easier tech upgrades.

Strategic Conclusion: Aligning Material with Brand Ambition

The choice is not about which material is universally better, but which is strategically right for your brand's current need.

Choose Fiberglass for: flagship stores, high-end boutiques, campaigns centered on artistry and premium craftsmanship, and for athletic mannequin displays where capturing precise, dynamic anatomy (like a running mannequin's form) is critical to the brand message.

Choose Plastic for: high-traffic retail, pop-up shops, large-scale rollouts, budget-conscious projects, and situations where durability and ease of logistics are priorities for your fitness mannequins.

By weighing the demands of durability, maintenance, cost, and visual impact against your specific retail strategy, you can select the mannequin material that not only displays your athletic apparel but actively enhances your brand's performance in the marketplace.