The evolution of specialized sports mannequins represents a significant advancement in retail display technology, with material science at its core. Unlike traditional retail forms, modern athletic male mannequin designs must withstand the rigorous demands of frequent pose adjustments while maintaining visual authenticity. The choice between advanced resin composites and reinforced fiber materials isn't merely aesthetic—it's an engineering decision that determines longevity, functionality, and return on investment in competitive retail environments.

Joint Durability: The Engineering Challenge of Dynamic Poses

The Stress Dynamics of Athletic Displays

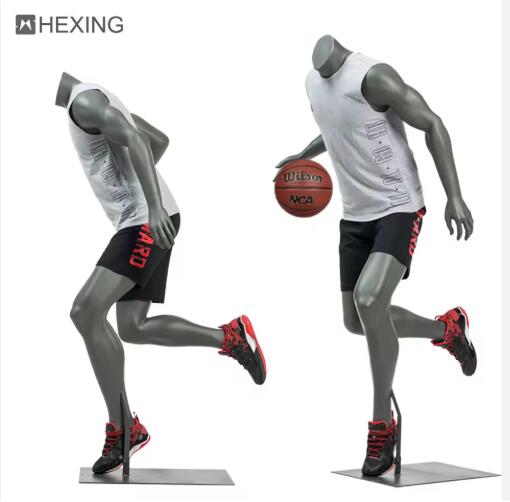

Professional Basketball player mannequin units face unique mechanical stresses distinct from other athletic displays. While a football player mannequin might emphasize grounded stability, basketball poses involve more extreme joint angles and off-center weight distribution. The fadeaway jumper, for instance, places asymmetrical stress on knee and hip joints that standard materials cannot sustain through repeated repositioning.

Advanced Composite Solutions

Leading manufacturers utilize glass-fiber reinforced polymers (GFRP) for high-stress joint areas, creating a material matrix that offers:

Impact Resistance: Withstands accidental contact during apparel changes

Fatigue Strength: Maintains integrity through thousands of pose adjustments

Precision Moldability: Allows for complex joint geometries that balance mobility with stability

Environmental Stability: Resists humidity and temperature variations that affect traditional plastics

This material approach enables a male sports mannequin to maintain precise joint tension—firm enough to hold challenging poses like a Euro-step layup, yet adjustable enough for seasonal display changes without degradation.

Surface Authenticity: Capturing Athletic Realism

Muscle Definition and Anatomical Precision

The surface treatment of an athletic mannequin serves dual purposes: visual authenticity and functional performance. Advanced molding techniques using silicone-modified resins create:

Defined Muscle Groups: Precise contours that reflect sport-specific physiqueSubcutaneous Detail: Subtle surface variations that mimic real tissue response

Sport-Specific Differentiation: Basketball physiques emphasizing vertical power versus football builds focused on horizontal strength

Textural Fidelity and Fabric Interaction

The surface texture of professional sports mannequins is engineered for optimal fabric presentation:

Micro-Texture Control: Surface roughness optimized at 5-15 microns to provide natural fabric drape without excessive clinging

Static Management: Material formulations that minimize static electricity, preventing awkward fabric positioning

Thermal Consistency: Materials that maintain neutral temperatures to prevent fabric distortion during extended displays

Comparative Material Strategies Across Sports

Basketball Versus Football Display Requirements

While both Basketball player mannequin and football player mannequin designs require durability, their material needs differ significantly:

Basketball Priority:

Joint Flexibility: Materials allowing 120°+ knee flexion for jumping poses

Weight Optimization: Lightweight composites for elevated poses

Surface Elasticity: Materials that suggest muscle tension during extension

Football Priority:

Impact Resistance: Enhanced protection for contact sport positioning

Stability Emphasis: Heavier bases and reinforced standing joints

Equipment Integration: Materials compatible with helmet and pad displays

This specialization explains why an athletic male mannequin designed for basketball may utilize different polymer blends than one intended for football, despite superficial similarities.

Manufacturing Innovations in Athletic Displays

Layer-Based Construction Techniques

Advanced manufacturing employs a multi-layer approach:

Structural Core: High-density polyurethane foam with carbon fiber reinforcement

Articulation Layer: Flexible thermoplastic polyurethane (TPU) at joint interfaces

Surface Finish: UV-resistant resin with embedded texturing agents

Protective Coating: Nano-scale ceramic coatings for scratch resistance

Quality Assurance Protocols

Each male sports mannequin undergoes:

Cycle Testing: 10,000+ pose adjustments without joint degradation

Environmental Simulation: Temperature/humidity extremes mimicking global retail conditions

Fabric Compatibility Testing: 50+ material types assessed for optimal presentation

Weight Distribution Analysis: Ensuring stability in sport-specific poses

The Retail Impact: Beyond Basic Display

Enhanced Customer Engagement

Properly engineered materials contribute directly to retail success:

Extended Product Life: High-quality composites reduce replacement cycles by 300-400%

Reduced Maintenance: Advanced materials minimize cleaning and repair requirements

Consistent Presentation: Stable materials ensure displays remain photogenic throughout campaigns

Brand Perception and Value Communication

When consumers interact with a professionally crafted athletic mannequin, they unconsciously transfer quality perceptions to the displayed apparel. The precision of muscle definition, the realism of skin texture, and the durability of joint mechanisms all communicate brand commitment to excellence—a subtle but powerful form of non-verbal branding.

Future Material Developments

Emerging technologies promise further advancements:

Self-Healing Polymers: Materials that repair minor surface scratches automatically

Phase-Changing Composites: Substances that adjust flexibility based on temperature

Integrated Lighting: Translucent materials with embedded illumination systems

Sustainable Alternatives: Bio-based resins with athletic display capabilities

The Science Behind the Display

The modern Basketball player mannequin represents a convergence of material science, biomechanical understanding, and retail psychology. Each component—from joint composites to surface textures—is engineered with specific performance goals that transcend basic display functions.

For retailers, understanding these material considerations isn't merely technical knowledge; it's commercial intelligence. Investing in properly engineered athletic male mannequin systems ensures displays that withstand operational demands while authentically representing athletic apparel's performance characteristics. In an increasingly visual retail landscape, these material decisions transform static displays into dynamic brand ambassadors that educate, engage, and ultimately convert today's discerning athletic consumers.

sports mannequins

athletic mannequin

male sports mannequin